Although connected objects are making a buzz and most large groups invest a lot in this domain, the revolution, as far as the general public goes, has not quite gone off yet.

Although connected objects are making a buzz and most large groups invest a lot in this domain, the revolution, as far as the general public goes, has not quite gone off yet.

While waiting for the announced perspectives, the IOT is showing substantial progress on industrial issues.

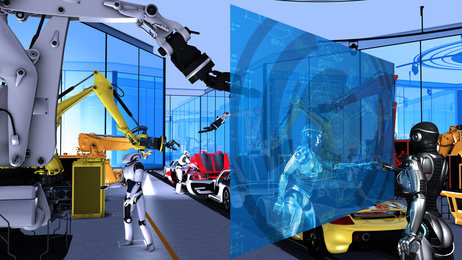

At the dawn of the fourth industrial revolution, the production chains are being improved as new applications are appearing, which considerably facilitate the production process.

But what really are these applications and their impact on business?

1/ From curative to preventative maintenance

The costs and negative impact that can come as a result of the production being interrupted can be considerable. However, it is possible to prevent this kind of incident, through the real-time and remote supervision of the functioning of the supply chain. Worn parts, overheating, vibrations, frictions, are reported immediately to the teams in order to anticipate and avoid anomalies. With this information handled upstream, factories can guaranty more constant production levels.

2/ Augmented reality, unlimited uses!

Augmented reality allows one to superpose virtual images onto real objects.

As a matter of fact, it allows an infinity of exploratory cases…

Without having specific mechanical knowledge, the augmented reality can, for example, accompany you in the reparation of a motor and therefore provide remote assistance by experts for technical interventions.

It can be used for training, quality control, R&D, industrial design, etc. the augmented reality revolutionizes the value of knowledge and widens the operational skills of certain profiles.

3/ collaborative platform and shared expertise

The development of the Cloud, digital tools and connected objects, helps to bring all the stakeholders together in interactive and decentralized centers.

Beyond sharing information, this kind of tool allows you to follow in real time the different phases of production, to facilitate the diagnostics and to accelerate and improve the decision-making procedures.

ARROWMAN Key Insight

The intelligent factory is one of the main strategic challenges for the development and improvement of the production tools. In order to anticipate and accelerate this transformation process, Benoit Andrade advises Directors and HRDs to:

? Define opportunities to improve the production tools and to establish the diagnostics that are necessary for the identification and integration of the profiles according to the maturity of the innovation projects.

? Set up adapted procedures for the research of highly coveted profiles to accompany change.

? Search for multiple competencies in order to facilitate interactions between business departments: Marketing and Information System knowledge, R&D and customer orientation, Managers of operational teams and innovation accelerators in the company, etc.

? Encourage the decompartmentalisation between specific departments of the company to build multidisciplinary teams.

Interactions between the different departments of the company are indispensable in order to constitute multidisciplinary teams that will be able to truly implement these changes.

Benoit ANDRADE, Managing Director at ARROWMAN Executive Search.